TOKYO KEIKI RAIL TECHNO INC.

|

|

[Ultrasonic Rail Inspection Car 'URIC']

The

ultrasonic rail inspection car's flaw detection system detects

internal rail flaws as the car runs along the rail and with the

distance measurement system option can provide accurate detection

of flaw position. The

ultrasonic rail inspection car's flaw detection system detects

internal rail flaws as the car runs along the rail and with the

distance measurement system option can provide accurate detection

of flaw position.

In addition to flaw detection, additional system

options include sectional wear measurement utilizing the newest

in image processing

technology and rail corrugation measurement using lasers.

The ultrasonic

rail inspection car has established an enviable record of shipments

to the Japan Railways companies including

the Shinkansen as well as every major private railway company.

<Features>

- Capable of high-speed ultrasonic rail inspection (40km/h).

- Manual calibration of position based on kilometer post references

for distance information. In addition, accuracy can be enhanced

using the "DataDepot" System (option) which detects

position data automatically.

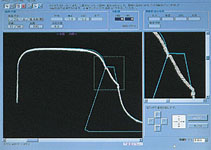

- Flaw data is presented in "B" scope color display

in real time. Also display recognition provides results of defect

type, classification and position data. Store and playback functions

are also provided which enable evaluation and discrimination

of natural defects and artificial "defects" such as

bolt holes, etc., which results in increased reliability of test

data. "A" scope display in real time is also available.

<Delivery milestones>

| 1965 |

Tokaido-Shinkansen (formerly Japan National Railway) |

| 1976 |

Sanyo-Shinkansen (formerly Japan National Railway) |

| 1983 |

Tohoku-Shinkansen (formerly Japan National Railway) |

| 1988 |

Tokyu Corporation |

| 1989 |

Central Japan Railway (Shinkansen) |

| 1990 |

Seibu Railway |

| 1992 |

West Japan Railway |

| 1996 |

East Japan Railway (Shinkansen) |

| 1997 |

Tobu Railway |

| 1999 |

West Japan Railway (Shinkansen)

Kyushu Railway |

| 2001 |

Keihin Electric Express Railway |

| 2003 |

Kinki Nippon Railway

Odakyu Electric Railway |

| 2004 |

Kyushu Railway (Shinkansen)

East Japan Railway

Seibu Railway |

| 2005 |

Hokkaido Railway |

| 2006 |

Central Japan Railway (Shinkansen) |

| 2008 |

Tokyu Corporation |

| 2009 |

West Japan Railway (Conventional Line No.2) |

|

[Switch profile gauge 'SPG-3']

'SPG-3S'

(standard gauge model) 'SPG-3S'

(standard gauge model)

'SPG-3N' (narrow gauge model)

The Switch Profile Gauge is a new system for automated turnout

inspection and maintenance.

The system adopts the light slice method

using a laser slit light source and two-dimensional CCD cameras.

The system simultaneously

measures the information necessary for calculating the wearing

depth of rails and crossings, back gauges, flangeway widths,

and track geometry. The system automates conventional manual

track

inspections and produces databases of measurement data which

incorporates office automation technology in the maintenance

and management

task.

|

<Features>

-

Light weight and user friendly operation

This device is pushed through a turnout manually. The data collection device is an easily transportable system that is making it light enough for two workers to carry, assemble and mount or dismount.

|

Sample display of wearing depth at tongue rail |

- Speedy measurement

Measurement times are 10 to 15 minutes per turnout since the system can simultaneously

measure the wearing depth of the rail and geometry of the track within

the turnout.

- Simultaneous measurement

The four parameters (gauge, longitudinal level, alignment and cross level)

pertaining to track irregularity can be measured simultaneously with respect

to the siding. Image data can be displayed on the screen in order to allow

visual confirmation of the wear depth of the rail.

- High precision measurement

|

| >> List of our services |